I got to wondering, always dangerous I find. I was just thinking, way down deep we have little control nor ability to verify just where the bore is located. Just how accurate is the actual location of a two section lateral at the end of the bore? Has anyone ever found that the drill wandered and was NOT where it was supposed to be? What do we have to rely on?

With today’s telemetry, they can hit their target 3 miles away from the vertical wellbore, generally within 10-20 feet of that intended target. Trust the survey.

I cannot fathom a system that could measure down over two miles in the ground of a pipe that small, or does it follow the drill portion on its journey? Does any institution actually check on those figures? Do they have the ability to “steer” the drilling?

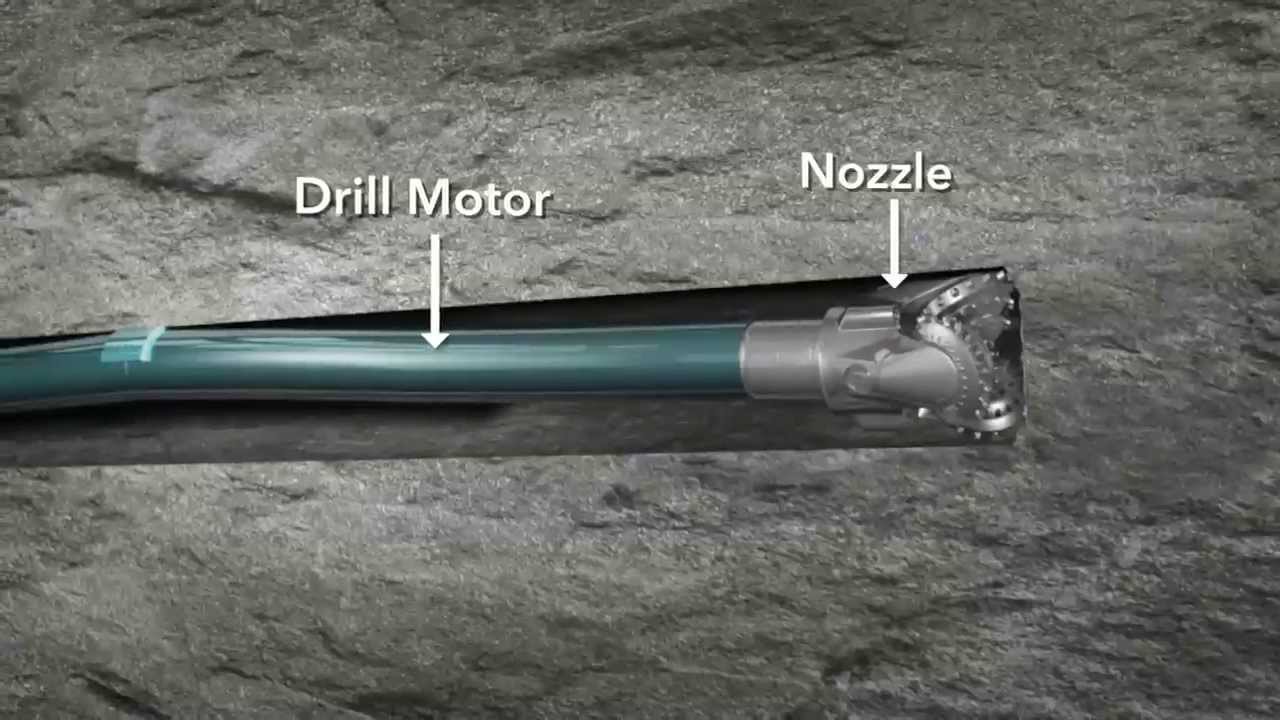

They now use down hole motors at the drillbit to steer the drill pipe. It is easier to pull a rope than to push one. And with the telemetry properties, the directional services company knows within a few feet of where the actual drillbit is in real space.

The companies that do the surveys of wellbore location are audited for practices and have to sign off on the results being accurate to the best of their ability. My husband is a land surveyor and it’s a bit along the lines of the same trust in “how do you know your fence/house/road is on your property.” There are scientific ways of measuring where things are above ground and below ground, but yes, the common person without that special equipment would never be able to verify it. There’s certainly cases of lawsuits regarding where the well ended up and having to re-survey the well (which can definitely be done, but costs a lot of money), but sometimes 20’ can mean millions of dollars. Sometimes 20’ means absolutely nothing.

I HAVE been part of a well where the geo/reservoir team wanted it drilled a certain way and sent off the requirements to the land and drilling team. Land came back and wasn’t able to put the surface location at the top of the section like originally planned and ended up putting the surface location at the bottom of the section (better land owner). Unfortunately the new location never made it through the process to the drilling team and the well was drilled into the wrong section.

Luckily in that case we had rights to drill that section, but the final well survey doesn’t lie as to where the well ends up going. If we didn’t have rights, the owners of that section would have had a free well drilled for them and we’d have zero rights to any royalties because there was no lease. There’d probably have been a lawsuit or two for something along the lines of trespassing.

These mistakes don’t happen often, but often enough that the RRC has plenty of checks along the way to know where the wells are all located and draining from. All of that ends up being filed with the RRC certifying “here’s how we actually drilled the well with coordinates and depths measured every ~100 feet or so.”

For how the bit is steered: The basic gist of it is there the drill bit can be angled and there are little rotating pieces that cut the rock depending on the angle the bit it hitting the rock. Technology is always changing, but they can communicate with the bit either through fiberoptic cable or through pulsing the fluids. There are also tools that measure where the bit is and what the rock is like as it is drilled to give the driller and geologist feedback as they go. Basically high tech compasses and carpenter levels (and other things) built in right behind the bit to send feedback uphole every 20-50 feet. The geologist is looking for certain geology to make changes on the fly as they go, which is called “geosteering” but still has to stay within a certain pre-approved window.

This video explains how the bit is steered better than I just did:

This topic was automatically closed after 90 days. New replies are no longer allowed.